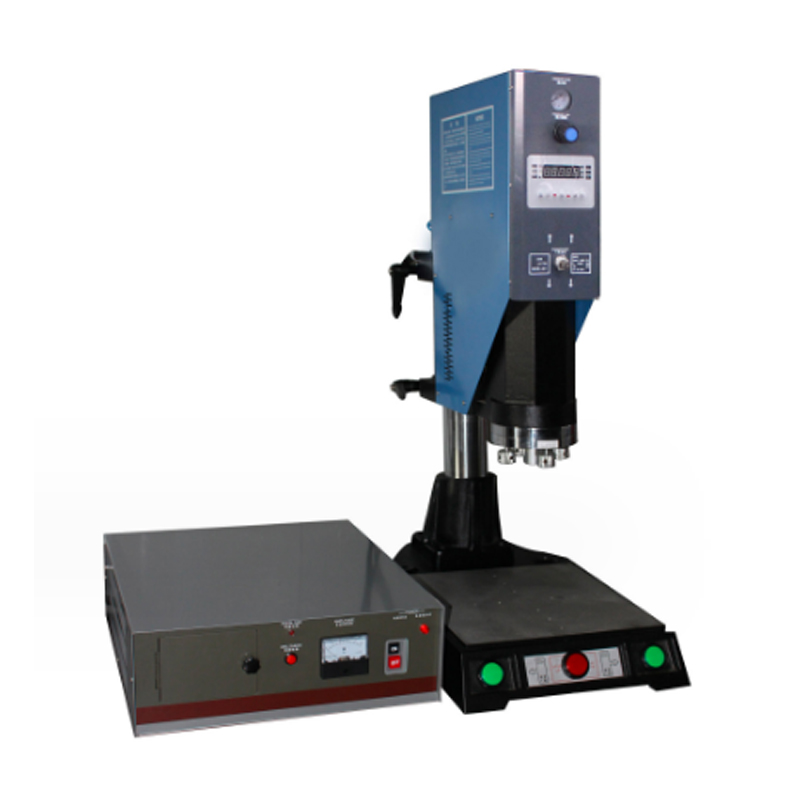

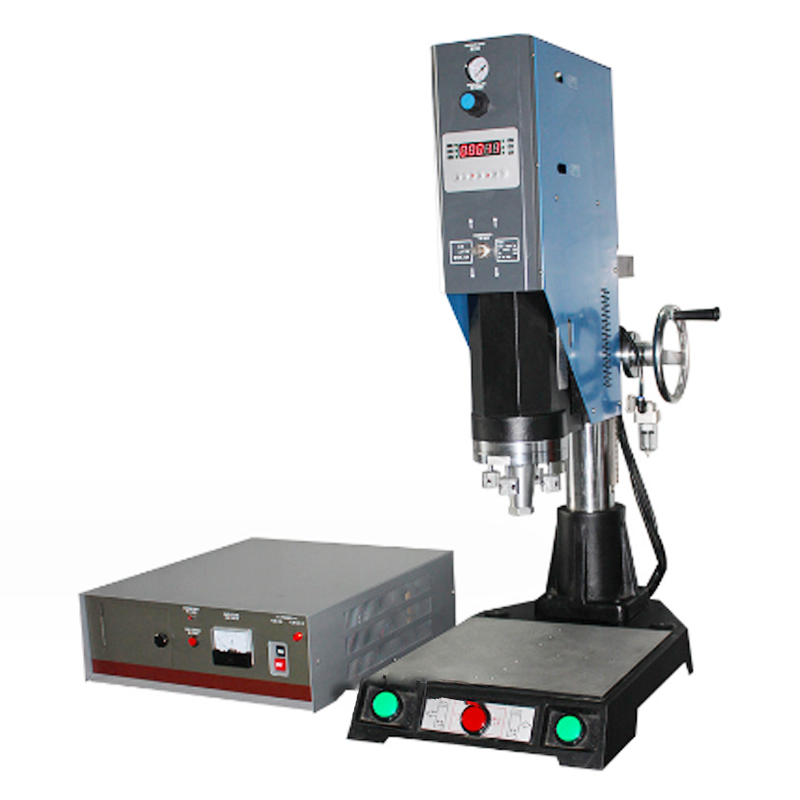

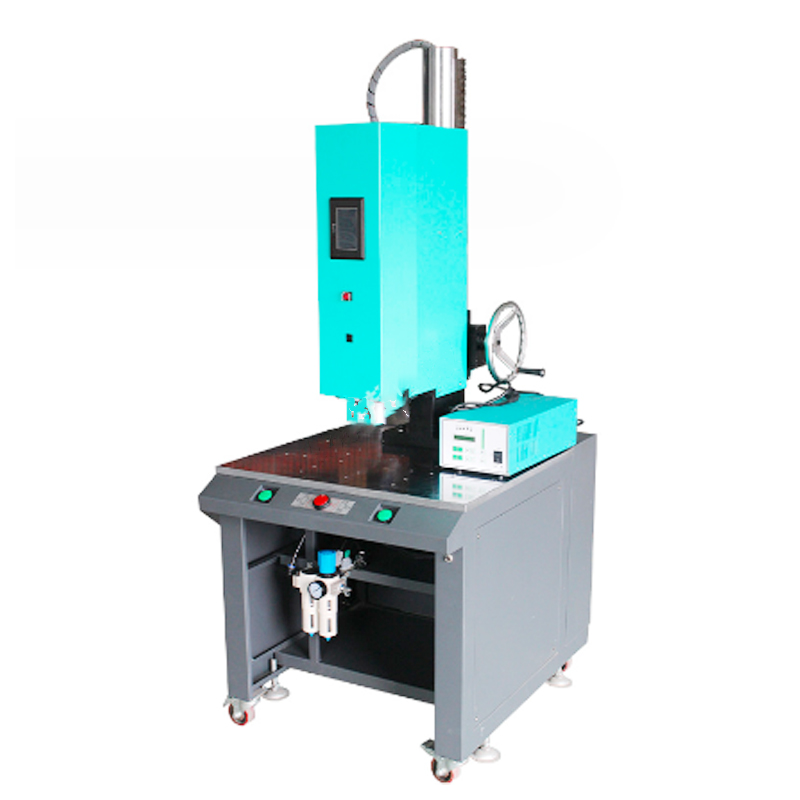

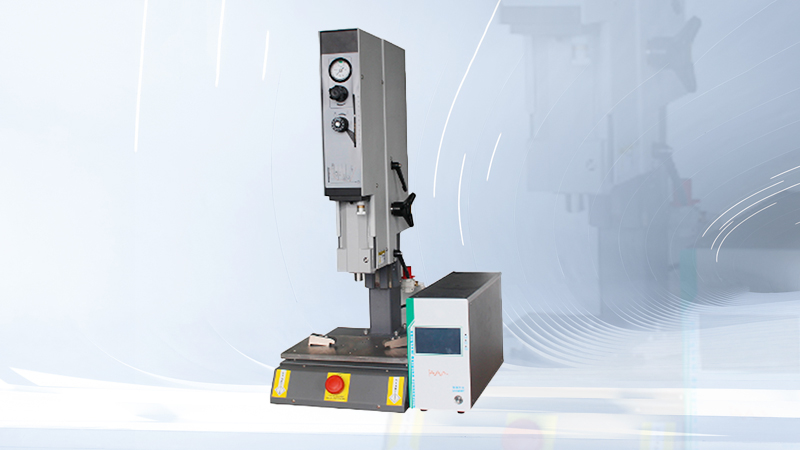

Ultrasonic Welding

Product features, product parameters, welding principles, application scope, usage instructions, maintenance methods:

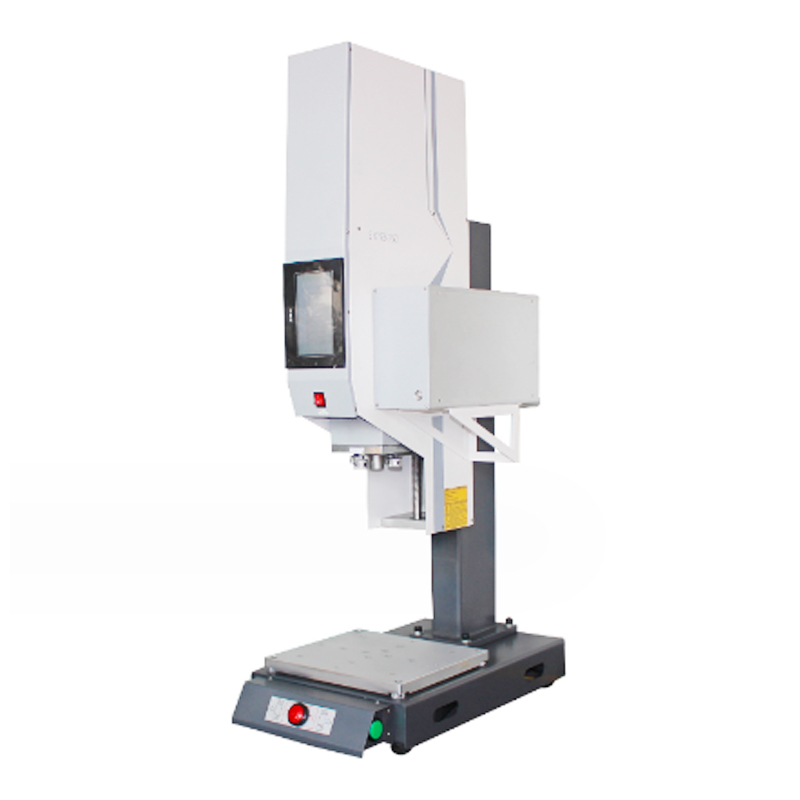

The difference between the intelligent ultrasonic welding machine and the ordinary machine is that the intelligent automatic frequency tracking machine has an automatic frequency tracking function, which does not require manual adjustment of the tuner when replacing the mold. It can automatically track the frequency point and has stable performance. For the regular type, the frequency must be manually adjusted after each mold change. If the mold is not adjusted properly, it will cause equipment damage.

Advantages of automatic frequency tracking ultrasonic welding machine:

1. Eliminating the inconvenience of manual frequency modulation, the frequency is automatically detected when turned on, making it more convenient and simple to use;

2. Built in various parameter computer digitization, automatic compensation amplitude, the amplitude is not large when unloaded, and the amplitude and power are synchronously amplified when the load increases, effectively protecting the transducer and welding head mold, resulting in higher welding accuracy;

3. The power output adopts digital stepless linear adjustment, with a free selection of output power from 50% to 100%. The internal power amplification adopts a full bridge IGBT module, which has a high ultrasonic conversion rate and a large ultrasonic power of 7200W, which can meet various welding requirements;

4. More advanced protection circuit, output sound wave overload, sudden mold rupture overload, built-in computer detection circuit to cut off output in a very short time, thus protecting internal circuits;

5. Up to 135 high-speed switching operations per minute, suitable for welding with various non-standard automation equipment;

6. The operation interface can be selected in Chinese or English, making it more convenient for foreign procurement.

Previous: Metal welding machine-2