The Best Products

Steps for replacing welding heads

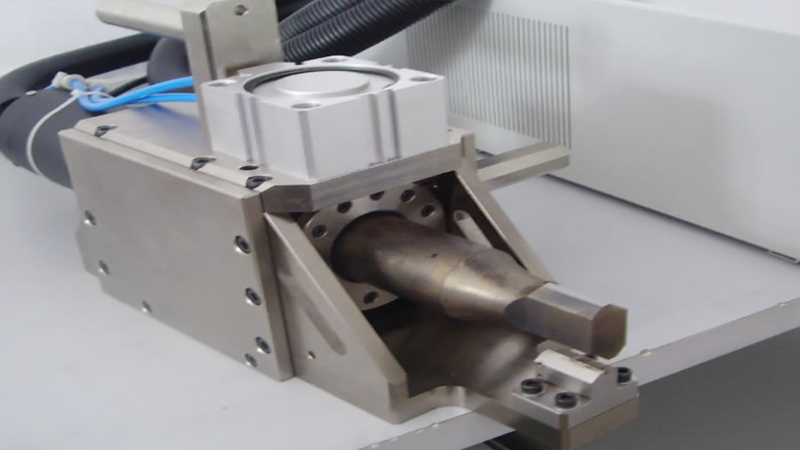

Adjustment steps for replacing the welding head of ultrasonic wire harness welding machine:

1. Remove the upper and front panels of the wire harness machine;

2. Loosen the fixing screws of the left module and lift it up a bit. Easy to remove vibration system;

3. Release the pressure block and remove the vibration system;

4. Replace the welding head and put it back in its original position;

5. Calibrate welding joints;

6. Reinstall the pressure block and tighten the vibration system.

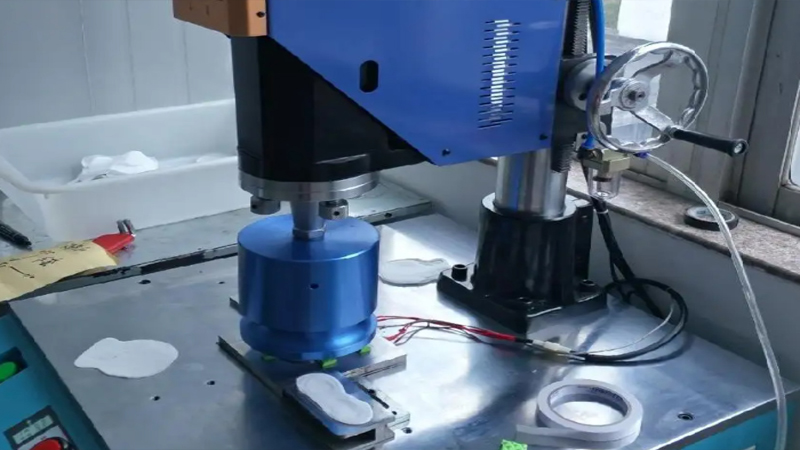

The cutting head of the ultrasonic welding machine for automotive wire harnesses mainly consists of four parts: welding head, anvil connection block, anvil top block, and polymer module. When welding, arrange a vertical connection tightly, close to the connection block anvil. After the foot switch, the polymer module moves towards the anvil block. At the same time, when the connection block is connected to the anvil block and the downward moving car harness is urgently pressed in the welding area, the welding head vibrates and transfers energy to the copper wire, causing the car harness to be welded together.