The Best Products

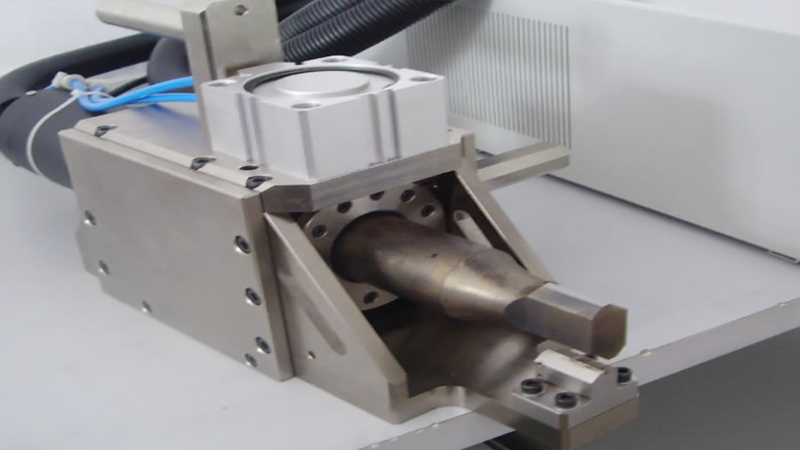

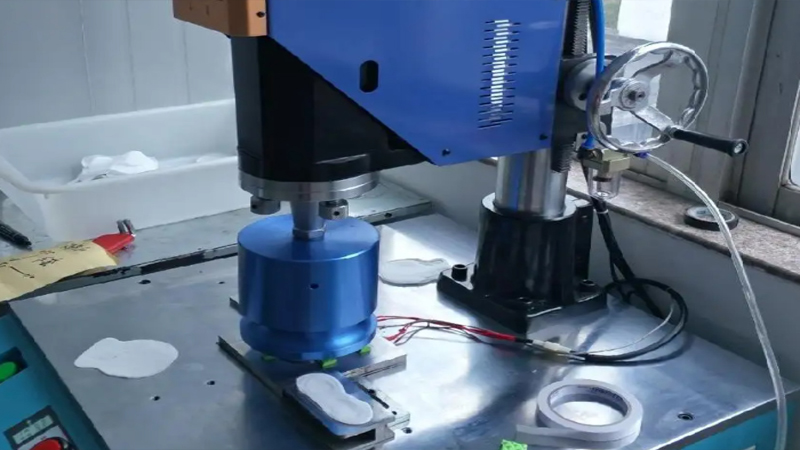

Parameter adjustment of ultrasonic wire harness welding machine

Adjustable parameters, detectable: amplitude, pressure, welding time, welding energy, welding height, welding width.

Pressure: The larger the cross-sectional area, the higher the welding pressure. Good equipment is digitally controlled by an electric proportional valve.

Welding width: According to the IPC standard and the German Volkswagen standard VW60307-CN-2005, the width to thickness ratio of the welding wire is between 1:1 and 2:1. The larger the cross-sectional area, the closer the width and thickness of the junction are to 2:1. So when we obtain wire harness products, we first determine the welding width based on this rule; Then determine the approximate welding height based on the width. The welding machine adopts a stepper motor or servo motor to adjust the welding width.

The welding time and welding energy need to be determined by trial welding based on the cross-sectional area of the welding wire. The height parameter is an important analytical parameter: after determining the welding width, we can calculate the height value based on the previous analysis. The height before and after welding can serve as a criterion for whether there is a missing line before welding and whether the welding is good.

Quality analysis mainly refers to the judgment of height; Of course, welding energy consumption and time can be used as additional constraint parameters to see if they exceed the range. General practice: Set a height value (which can be determined through actual welding test calculations), and then set a deviation value. When the height deviation exceeds the range, it can be judged as unqualified. This is true before and after welding.