The Best Products

Reasons for high current in ultrasonic welding equipment and solutions

Today, the manufacturer of ultrasonic welding equipment will take you to analyze the reasons for the high current of ultrasonic welding equipment and the solutions:

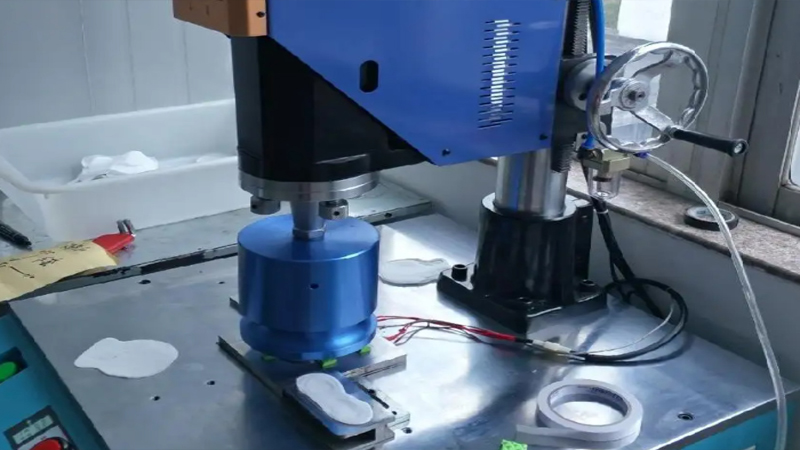

The current of ultrasonic welding equipment is very high. Firstly, it is necessary to distinguish between the current caused by component damage of ultrasonic welding equipment itself or the current caused by ultrasonic load output problems. It's very simple. Remove the ultrasonic output line and test the current of the ultrasonic generator without load. If it is normal, it means that the ultrasonic vibration system is faulty.

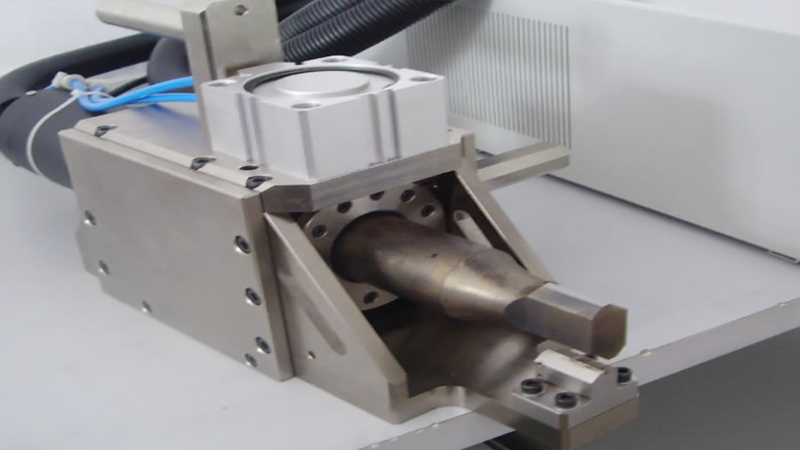

Experience has shown that the high electromechanical flow rate of ultrasonic welding is usually caused by a mismatch between the ultrasonic vibration system and the ultrasonic welding equipment. To address this issue, check whether all components of the ultrasonic vibration system are functioning properly, whether the connections between screws are loose, and whether there are cracks in the ultrasonic welding equipment.

1. Loose screws between ultrasonic welding equipment and transducers result in high current, which usually occurs in machines that have been in use for a period of time. The elimination method is to tighten the ultrasonic mold head special wrench and check if the mold head is locked tightly.

2. Replace the vibration of the ultrasonic transducer or ultrasonic welding equipment. If the current is too high after replacing these two parts, it is normal.

3. Damage or rupture of ultrasonic molds or mold heads usually occurs when used for too long or when ultrasonic waves are used for too long. The method of elimination is to check whether there are cracks on the surface of the mold head or install it in another ultrasonic system for testing.

Previous: Special ultrasonic welding head

Next: No More