The Best Products

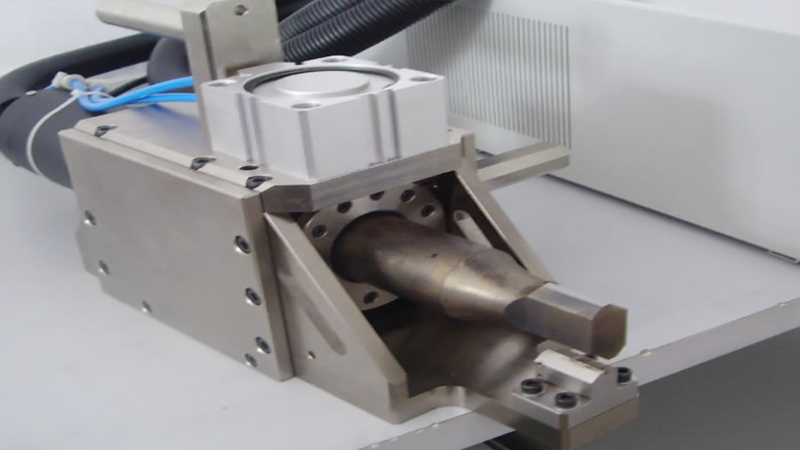

Special ultrasonic welding head

1. What is an ultrasonic welding joint:

Ultrasonic transmitter is a general term for all ultrasonic transmitters and an indispensable part of ultrasonic welding equipment. Its function is to couple the ultrasonic waves generated by the transducer to the processed object. Due to the need to emit ultrasonic waves, the welding head must work in a resonant state, that is, its inherent resonant frequency must match the transducer. The second is that the amplitude should be uniform, and the shape of the welding head end face should be suitable for the shape of the workpiece to be welded.

2. Ultrasonic welding head material:

Titanium alloy, magnesium alloy, aluminum alloy, powder metallurgy steel, etc.

3. Customized ultrasonic welding head:

The design of ultrasonic welding heads is not a simple shape. On the contrary, it requires a lot of professional knowledge and skills to ensure that the welding head can effectively transmit the mechanical vibration converted by the transducer to the workpiece, forming a continuous and stable welding effect. We still firmly believe that only through strict testing and quality control can we produce good welding heads. By applying ultrasonic mold analysis software to simulate the actual state of welded joints, our engineers combine the acoustic and mechanical characteristics of welded joints to design the products that customers need.

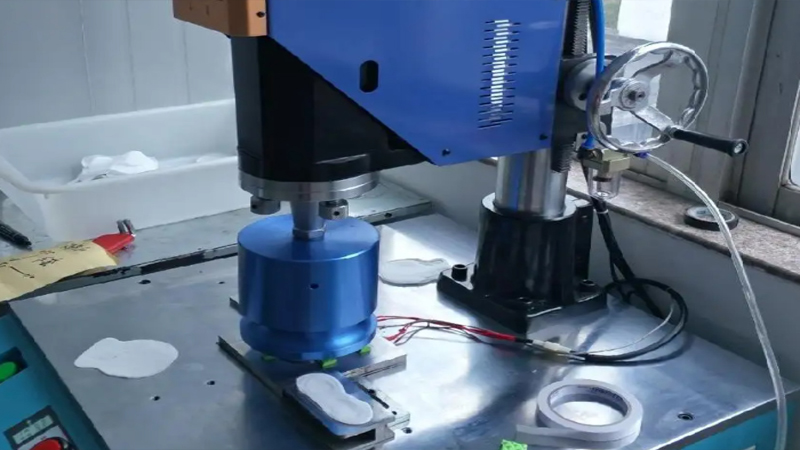

4. Precautions for ultrasonic metal welding joints:

Ultrasonic metal specialized welding heads are an indispensable part of ultrasonic metal welding equipment. Its function is to transmit the high-frequency vibration generated by the transducer to the acoustic components of the upper workpiece, as well as the working surface that directly contacts the metal workpiece during operation. Due to repeated friction under high temperatures for a long time, the wear is more severe. To ensure the product qualification rate, this component needs to be replaced regularly.