The Best Products

Issues to be noted when replacing vibration systems

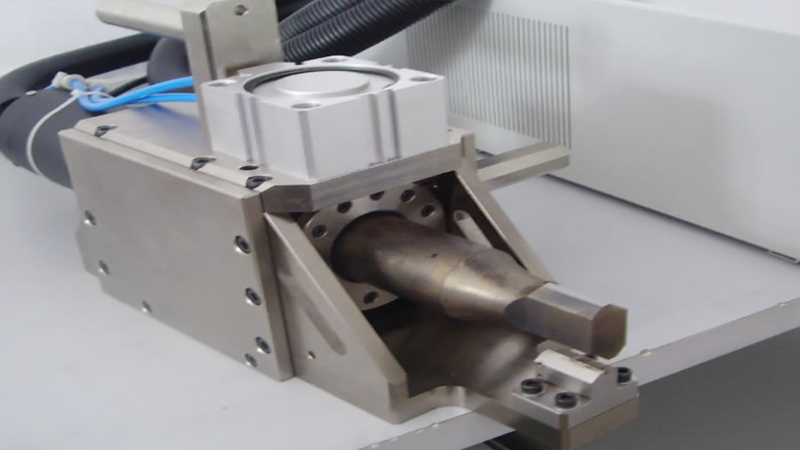

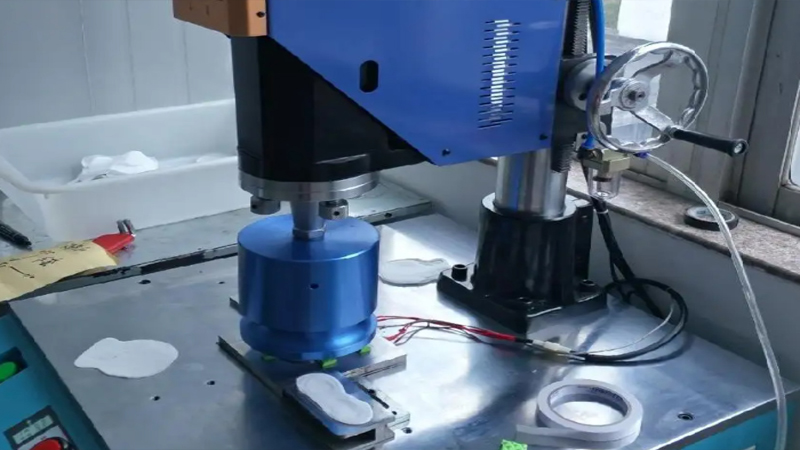

When replacing the vibration system of ultrasonic wire harness welding equipment, attention should be paid to the following issues:

1. Carefully observe whether the connecting bolt lines are complete to avoid damaging the screw buds of the vibration system due to vibration. Replace if necessary to avoid excessive losses.

2. The connection surface must be clean and free of dust and debris. Butter should be added during installation to improve ultrasonic transmission.

3. After tightening the bolt onto the welding head, loosen it by half a turn to prevent the bolt from crushing the welding head, and then tighten the bolt onto the diode. To install the secondary pole and transducer, the bolts must be fixed to the secondary pole before installing the transducer. The order cannot be reversed, please be careful!

After the replacement is completed, please do not immediately install it on the machine. Connect the cables and directly place the vibration system on the table to test for any abnormalities in the ultrasound. a) When there is strange noise, please reinstall the vibration system. b) Intermittent ultrasound playback for 2-3 minutes, and the duration of each ultrasound trigger should not be too long. Please reinstall when checking the heating condition (the connection surface may not be clean).

Previous: No More

Next: Reasons for high current in ultrasonic welding equipment and solutions