Hot melt machine

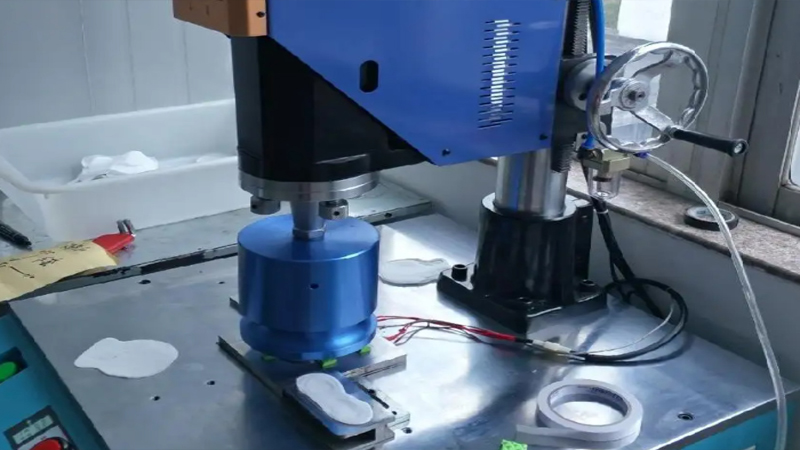

Biken hot riveting machine is a type of plastic riveting machine that uses inherent plastic riveting columns, ribs, and folded edges reserved on a hot melt plastic component. After controlled hot melt softening, it is then compacted, cooled, and reshaped and clamped with a cold riveting head. By using a specific shape of riveting head, it can achieve buried hot riveting (flat hot riveting) of plastic riveting columns, hemispherical plastic hot riveting machine hot riveting, arc flanged hot riveting, ribbed hot riveting, mechanical forging, folded edge inlay coating, etc, A connecting machine that combines materials of different materials, plastic, hot riveting, mechanical riveting, and assembly together.

Product design:

1. The electrical control part adopts human-machine interface and PLC control; 2. Adopting a plastic hot riveting machine with dual button start design, improving practical safety, and an emergency stop protection device to ensure production safety; 3. Adopting engineering design, reasonable structure, and safe use; 4. The appearance design of this machine is exquisite; 5. Specification parameters: Power: 1800w-4200w; 6. Scope of application: For some plastic products that cannot be hot riveted on the front or are difficult to be hot riveted on the front

Specific application scope:

Hot riveting of plastic and metal materials; Plastic and plastic hot riveting; Hot riveting of plastic and metal mesh; Hot riveting of plastic and bakelite; Hot riveting of plastic and fiber woven materials such as synthetic leather or leather.

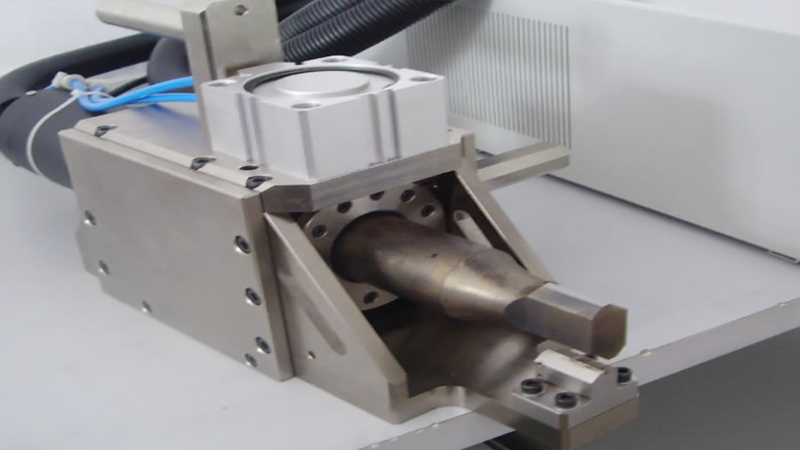

Hot riveting machines generally adopt a pressure plate structure, and the heat from the heating plate is transferred to the hot riveting head by the electric heating method. The hot riveting head heats the riveting column to melt it, and then blows it to cool and solidify, forming the riveting head and fixing the product. The whole machine is in the form of a frame, consisting of two large plates: the upper mold (hot riveting head) and the lower mold, and the action mode is pneumatic control. Mainly suitable for welding plastic parts such as household appliances, car lights, and car solvents. Heating power and mold size can be set according to different sizes of plastic parts to achieve various plastic workpiece welding, with simple operation and convenient use. The upper mold is composed of a heating plate, a hot riveting head, and a blowing tube. It is heated by an electric heating tube, and the blowing tube is cooled and solidified.

The control mode of this equipment can be divided into manual and automatic. Manual is a single piece action, mainly used for debugging mechanisms and molds. After manual debugging, it can be adjusted to automatic during production. The automatic control system adopts programmable logic controller (PLC) and touch screen human-machine interface for control. The movement of each cylinder is driven by air pressure, which is easy to operate, reliable in performance, compact in size, and improves production efficiency and quality.

Previous: Ultrasonic rotary welding machine